OPTIMISING ENERGY EFFICIENCY

The European Union committed to meeting its three main climate and energy targets for 2020 when it adopted the Kyoto Protocol in 1997:

- 20% cut in greenhouse gas emissions (and Carbon dioxide CO2 in particular) by 2020

- 20% of EU energy from renewables

- 20% improvement in energy efficiency

The purpose of Directive EC 125/2009 establishing a framework for the setting of ecodesign requirements for energy-related products (ErP Directive) is to ensure that manufacturers and importers make and distribute high energy efficiency products to protect the end user.

The Ecodesign Directive came into effect in the European Economic Area (EEA) on 1 January 2016.

ENERGY LABELLING REFERENCE PARAMETERS

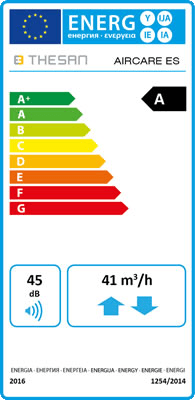

Specific Energy Consumption (SEC) is the reference parameter. This is calculated using a complex equation set forth in Annex VIII of Commission Regulation (EU) No 1253/2014 with regard to ecodesign requirements for ventilation units. The equation combines performance data from laboratory tests with standardised climate data. The final result of the calculation – always negative – is expressed in Primary Energy generated by the difference between the energy used to power the unit and the energy recovered and/or maximised by the control equipment. The energy label also specifies the maximum flow rate and the corresponding sound power level.

Commission Regulation (EU) No 1253/2014 and Commission Delegated Regulation (EU) No 1254/2014 supplementing Directive 2010/30/EU with regard to energy labelling of residential ventilation units. The ecodesign requirements covers systems with an electric power input of more than 30 W per air stream. Ventilation units (e.g. single room systems) with very low energy consumption are exempted from the labelling requirements.

SAVING ENERGY: AIRCARE IS IN POLE POSITION

So, Aircare ES doesn't need an energy label because it consumes 10 W per air stream.

Still, the SEC is specified in the Instructions and in the Technical Datasheet. This parameter is useful to classify the unit and to appreciate its energy efficiency.

When Aircare is correctly sized for the home it is to be installed in, it assures the air flow required by standard ISO 17772-1:2017: 14.4 m3/h per person, with a thermal efficiency of up to 82%. This performance level is extremely high for a single-point system; at the same time, it is fully compliant with the standard in terms of air change.

It is important to consider that, in order to achieve a higher level of efficiency, the correct air change required may be compromised, which in turn means not being compliant. The table below shows the relationship between thermal efficiency and air flow.

VENTILATION FOR BUILDINGS - COMPONENTS/PRODUCTS FOR RESIDENTIAL VENTILATION

UNI EN 13141 is the standard used by the TÜV SÜD laboratories as the basis for their tests on residential ventilation units and components. The standard is broken down into 11 parts, depending on the type of product to test.

Product standards for ventilation systems

| UNI EN 13141 | Title: Ventilation for buildings - Performance testing of components/products for residential ventilation |

|---|---|

| Part 1 | Externally and internally mounted air transfer devices. |

| Part 2 | Exhaust and supply air terminal devices. |

| Part 3 | Range hoods for residential use without fan. |

| Part 4 | Fans used in residential ventilation systems. |

| Part 5 | Cowls and roof outlet terminal devices. |

| Part 6 | Exhaust ventilation system packages used in a single dwelling. |

| Part 7 | Performance testing of a mechanical supply and exhaust ventilation units (including heat recovery) for mechanical ventilation systems intended for single family dwellings. |

| Part 8 | Performance testing of un-ducted mechanical supply and exhaust ventilation units (including heat recovery) for mechanical ventilation systems intended for a single room. |

| Part 9 | Externally mounted humidity controlled air transfer device. |

| Part 10 | Humidity controlled extract air terminal device. |

| Part 11 | Supply ventilation units. |